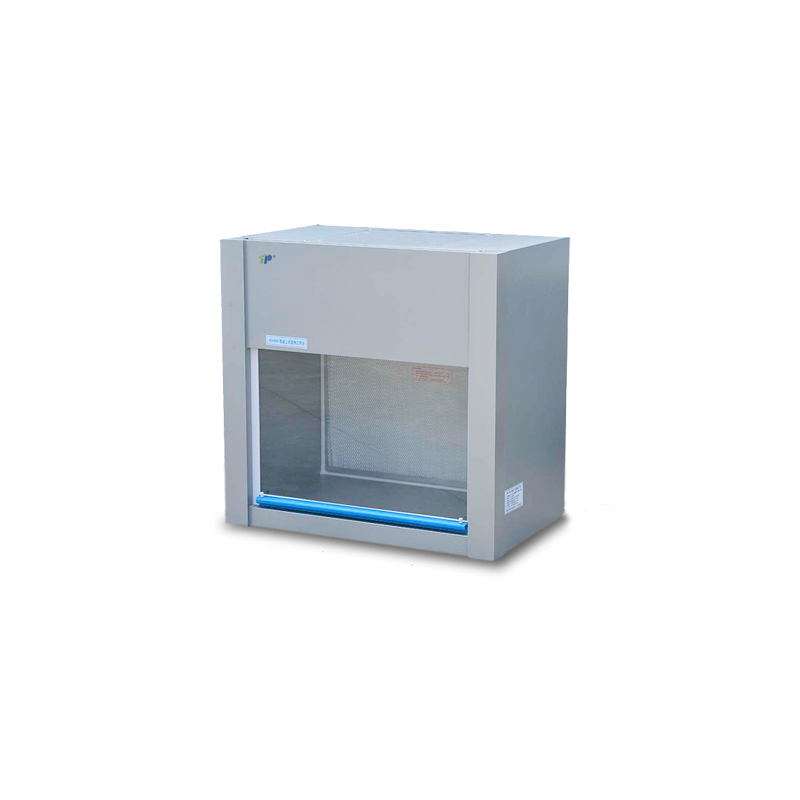

A clean bench is a piece of equipment that creates a clean, particle-free workspace by blowing filtered air in a smooth, consistent airflow (called laminar airflow). It uses HEPA filters to remove dust, microbes, and other contaminants from the air. This helps protect sensitive materials—like biological samples, electronics, or medical devices—from being contaminated.

Clean Bench vs Lab Fume Hood vs Biological Safety Cabinets

Application Scenarios

Biological laboratories

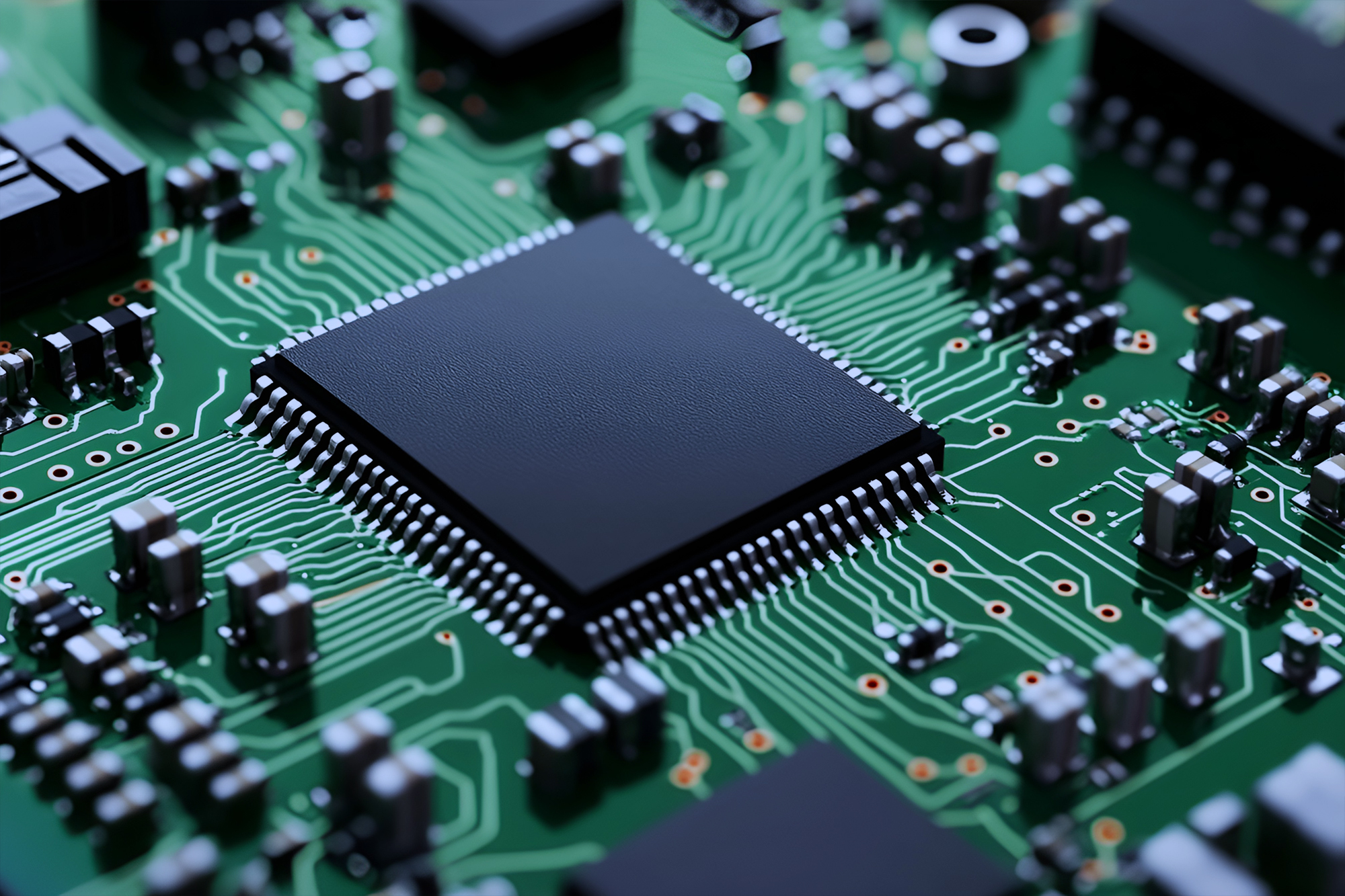

Electronics manufacturing

Pharmaceutical production

Food quality control

Medical & healthcare settings

Research institutes

Clean benches rely on two essential mechanisms to keep the workspace free of contaminants: laminar airflow and HEPA filtration.

Horizontal or Vertical Laminar Flow Hoods?

Both Vertical Laminar Flow Clean Bench and Horizontal Laminar Flow Clean Bench have their own advantages when it comes to preventing contamination. The best choice depends on the type of samples being performed and how objects are positioned within the airflow.

When an object is introduced into the clean airflow, it disrupts the airflow due to its shape—since most objects aren’t perfectly aerodynamic. This can cause localized turbulence, which reduces airflow efficiency and may allow mixing between clean and contaminated air. In some cases, this turbulence can travel downstream or even pull particles back upstream toward the object, compromising the protective effect of the laminar airflow.

Laminar airflow refers to a smooth, unidirectional flow of filtered air that moves at a constant speed and in parallel layers, with minimal turbulence.

| Horizontal Laminar Flow Clean Bench | Vertical Laminar Flow Clean Bench | |

| Airflow Direction | Blows from the back toward the operator | Blows vertically from top to bottom |

| Advantages | Shorter airflow path, more direct cleanliness | Air does not blow directly at the operator; safer |

| Disadvantages | Air blows toward the user — not ideal for volatile samples | Operator's hands or tools may obstruct airflow |

| samples | a large horizontal surface and/or a narrow cross section | a large cross section and/or a narrow horizontal surface |

| Typical Applications | Electronics, dust-free assembly, general lab use | Pharmaceutical prep, microbiology, cell culture |

ISO Cleanliness Grades

The ISO Cleanliness Grades is defined by the ISO 14644-1 standard and is widely used to measure airborne particle concentrations in cleanroom environments. ISO classes range from Class 1 (extremely clean) to Class 9 (less clean), based on the number and size of particles per cubic meter of air.

Before ISO Cleanliness Grades became widely adopted, the United States commonly used the Federal Standard 209E (FED STD 209E). This system classified cleanrooms by the number of particles ≥0.5 µm per cubic foot of air—such as Class 100, Class 10,000, and Class 100,000. Although officially withdrawn in 2001, FED STD 209E is still referenced in many industries due to its simplicity and long-standing use.

ISO Cleanliness Grades & FED STD 209E

| 209E(Class) | Maximum particles/ft^3 | ISO (Equivalent) | ||||||||

| ≥0.1 μm | ≥0.2 μm | ≥0.3 μm | ≥0.5 μm | ≥5 μm | ||||||

| 1 | 35 | 75 | 3 | 1 | 0.007 | ISO 3 | ||||

| 10 | 350 | 75 | 30 | 10 | 0.07 | ISO 4 | ||||

| 100 | 3500 | 750 | 300 | 100 | 0.7 | ISO 5 | ||||

| 1000 | 35000 | 7500 | 3000 | 1000 | 7 | ISO 6 | ||||

| 10000 | 350000 | 75000 | 30000 | 10000 | 70 | ISO 7 | ||||

| 100000 | 3.5x10^8 | 750000 | 300000 | 100000 | 700 | ISO 8 | ||||

Classification of Clean Bench

Vertical Laminar Flow Clean Benches

Deliver filtered air vertically from top to bottom, offering high contamination control for sensitive experiments. Ideal for microbiology, tissue culture, and sample preparation.

Portable Clean Benches / Tabletop Models

Compact and moveable units suitable for flexible or temporary setups, field labs, or space-limited environments

Horizontal Laminar Flow Clean Benches

Provide laminar airflow across the work surface from back to front, ensuring operator comfort and uniform air distribution. Widely used in electronics, precision instruments, and sterile packaging.

PCR Cabinets / PCR Workstations

Specialized vertical laminar flow benches equipped with UV sterilization for nucleic acid work (PCR setup, molecular diagnostics), minimizing DNA/RNA contamination

FAQ

Choose a location away from direct sunlight, air vents, and high-traffic areas. This helps prevent external airflow disruption and keeps the working environment clean and stable.