TO MAKE THE WORLD CLOSER TO THE TRUTH

TO MAKE THE WORLD CLOSER TO THE TRUTH

TO MAKE THE WORLD CLOSER TO THE TRUTH

Views: 0 Author: Site Editor Publish Time: 2025-06-12 Origin: Site

Maintaining a clean and contamination-free environment is essential in modern laboratories, where even the smallest particles can compromise sensitive experiments, damage equipment, or endanger health. To achieve this, laboratories commonly rely on specialized equipment such as clean benches and biosafety cabinets.

However, these two types of equipment are often mistakenly used interchangeably. While they may look similar and both provide filtered airflow, their purposes and protective functions differ significantly.

This article aims to clarify the key differences between clean benches and biosafety cabinets, helping lab managers, technicians, and researchers make informed decisions when selecting the right equipment for their specific applications.

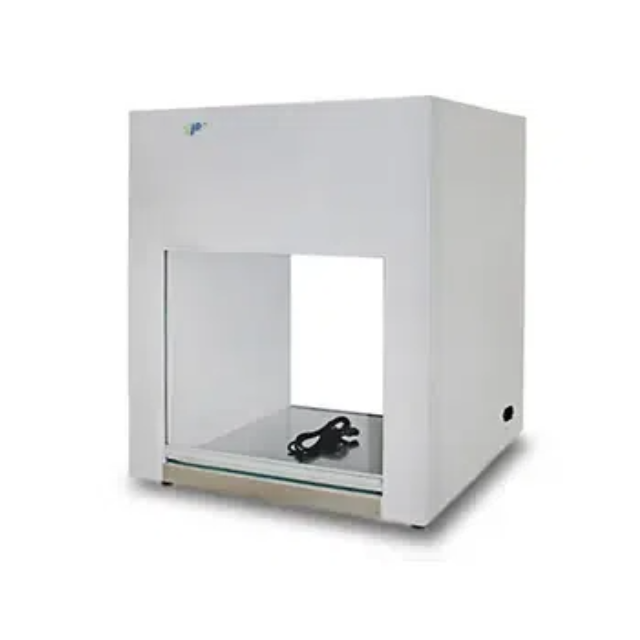

A Clean Bench is a lab workstation that provides a contamination-free area by delivering HEPA-filtered laminar airflow across the work surface. This airflow moves steadily toward the operator, keeping the workspace free from dust and particles.

The laminar airflow in a clean bench flows in parallel layers, minimizing turbulence and preventing contaminants from settling on samples.

Aseptic operations like media preparation

Electronics assembly requiring dust-free conditions

Handling non-hazardous biological or chemical samples

While Clean Benches are designed to protect samples from external contamination, Biosafety Cabinets (BSCs) take laboratory protection a step further. These advanced containment units are engineered to safeguard not only the work materials but also the operator and the surrounding environment.

A Biosafety Cabinet is an enclosed, ventilated laboratory workspace designed to handle potentially hazardous biological agents. Unlike Clean Benches, which direct filtered air toward the user, BSCs are equipped with HEPA (High-Efficiency Particulate Air) filters that control airflow in a way that protects both the product and personnel.

Inside a BSC, air is drawn through HEPA filters to remove airborne contaminants before it enters the workspace. Contaminated air is then either recirculated through additional filters or safely exhausted out of the cabinet. This dual protection makes BSCs ideal for handling biohazardous materials.

Biosafety Cabinets are categorized into three main classes, each serving a specific level of containment:

Class I BSC: Provides personnel and environmental protection, but not product protection. Suitable for low- to moderate-risk biological materials.

Class II BSC: Offers comprehensive protection—personnel, product, and environment. This is the most commonly used class in microbiological research and clinical labs.

Class III BSC: Also known as a glove box, it provides maximum containment for high-risk pathogens and is gas-tight with a sealed design.

Unlike Clean Benches, which are unsuitable for biohazard work, Biosafety Cabinets are essential in environments where infectious or toxic agents are present. Common applications include:

Handling pathogens or genetically modified organisms (GMOs)

Conducting virology and microbiology research

Working in clinical diagnostic labs and pharmaceutical development

Performing vaccine production or cell culture involving infectious agents

Feature | Clean Bench | Biosafety Cabinet |

Sample Protection | ✅ Yes | ✅ Yes |

Operator Protection | ❌ No | ✅ Yes |

Suitable for Biohazards | ❌ No | ✅ Yes (Class II & III) |

Airflow Direction | Laminar, toward operator | Vertical or recirculated, with filtered exhaust |

Common Applications | Media prep, electronics, sterile packaging | Microbiology, pathogen handling, pharma labs |

Clean Benches are designed only to protect the product or sample from airborne contamination. They are not built to protect the user or the environment.

Biosafety Cabinets, on the other hand, provide comprehensive protection—for the sample, the operator, and the laboratory environment—making them suitable for work involving biological hazards.

Clean Benches use laminar (unidirectional) airflow that typically moves from the rear of the unit toward the user. This airflow can actually blow contaminants directly into the user’s breathing zone if hazardous materials are involved.

Biosafety Cabinets use a combination of inward, downward, and filtered exhaust airflow, preventing contaminants from escaping the work area and thus protecting both the user and the surroundings.

Clean Benches are ideal for non-hazardous applications like:

Media preparation

Electronics assembly

Sterile packaging of lab materials

They should not be used with infectious agents or unknown biological samples.

Biosafety Cabinets are appropriate for:

Handling of biohazards and pathogens

Clinical and pharmaceutical research

Cell culture involving infectious materials

Choosing the wrong type of equipment can pose serious risks:

Using a Clean Bench where operator protection is required violates laboratory safety protocols and can lead to exposure to harmful agents.

Most safety regulations (e.g., from CDC, WHO, or NSF) prohibit the use of clean benches for work involving hazardous biological agents.

In summary, while Clean Benches are excellent for maintaining a sterile workspace for samples, they do not offer personal protection and must never be used for hazardous work. For any operation involving infectious or potentially harmful materials, a properly classified Biosafety Cabinet is essential.

Making the right distinction helps protect your team, ensures compliance, and supports a safe and effective laboratory environment.

Selecting the appropriate laboratory equipment is crucial to ensure both effective contamination control and safety. When it comes to Clean Benches, making an informed choice depends on understanding your specific application needs and compliance requirements.

Identify Your Application Needs

Determine whether your work involves handling hazardous biological agents or non-hazardous materials. For tasks such as sample preparation, electronics assembly, or sterile packaging—where only product protection is necessary—Clean Benches provide an ideal solution.

Assess Safety Requirements

If your lab handles infectious or biohazardous materials, operator and environmental protection become paramount. In such cases, a Biosafety Cabinet—not a clean bench—is the appropriate choice.

Match Equipment to Risk Level

Laboratories performing high-risk pathogen research or clinical diagnostics must adhere to strict safety protocols, which dictate the use of suitable containment equipment.

Operator Exposure

Using a Clean Bench for biohazardous work exposes laboratory personnel to airborne pathogens due to the airflow design, which does not protect the operator.

Cross-Contamination

Inadequate containment may lead to contamination of the lab environment or samples, compromising experimental integrity and possibly causing health hazards.

Regulatory and Legal Consequences

Non-compliance with safety regulations can result in fines, lab shutdowns, or legal liabilities, impacting your organization’s reputation and operations.

Follow Established Guidelines

Regulations such as NSF/ANSI 49 in the United States specify design, performance, and testing requirements for Biosafety Cabinets to ensure personnel and product safety.

Understand Limitations of Clean Benches

Clean benches typically do not fall under stringent biosafety standards because they lack operator protection. Using them outside their intended purpose may violate lab safety codes.

Consult Industry Standards

Always refer to national and international standards relevant to your industry and application to ensure your equipment selection aligns with legal and safety requirements.

While Clean Benches and Biosafety Cabinets may appear similar, their functions and safety features are fundamentally different. Clean Benches provide product protection through laminar airflow but offer no protection to the operator, making them ideal for non-hazardous tasks. In contrast, Biosafety Cabinets are designed to protect both the user and the environment, and are essential for handling infectious or biohazardous materials.

Choosing the right equipment depends on your specific application and safety requirements. Misuse can compromise both safety and compliance.

For reliable guidance and high-quality lab solutions, it's best to consult experienced suppliers like Zhejiang Top Instrument Co., Ltd., who can help you select the most suitable equipment—whether you're working with sensitive samples or hazardous agents.